Winter welder gloves

## welder gloves winter: protection and comfort in the cold

Winter is a harsh season, especially for those who work outdoors. Welding, whose work is already associated with high temperatures and potential dangers, encounter a double load in winter: it is necessary to provide protection from sparks and splashes of molten metal, as well as from cold and wind. Therefore, the choice of correct gloves is a question not just comfort, but safety and health.

### Requirements for winter gloves for welding

Winter gloves for the welder should combine several important qualities. First of all, this, of course, is protection against thermal influences. They must withstand high temperatures, do not melt and not ignite from sparks and spray. The material of the gloves should be dense enough to prevent the burners, but at the same time flexible enough to ensure the necessary freedom of movement.

It is equally important to ensure protection against cold and moisture. Wet hands quickly freeze, which reduces sensitivity and performance. Therefore, ideal winter gloves for welding should be made of waterproof material that preserves heat well. An additional layer of insulation inside the gloves will become a real salvation in severe frost.

### Selection of Material and Construction

When choosing winter gloves, pay attention to the material of manufacture. The skin, as a rule, is one of the most popular materials due to its strength and resistance to high temperatures. However, the skin can be hard enough, so it is worth considering combined options using synthetic materials that add flexibility and thermal insulation. For example, a combination of skin and special insulation tissues can provide an optimal balance of protection and comfort. Also, pay attention to the length of the gloves - longer models better protect the wrists from the cold and spray.

### Comfort and convenience - the key to productive work

Do not forget about comfort. Unknown gloves will interfere with work, causing irritation and discomfort. Pay attention to the planting of gloves, the presence of ergonomic shape and comfortable fasteners. It is good if gloves have an anatomical cut that repeats the shape of the hand. Properly selected gloves will allow the welder to focus on their work, ensuring safety and efficiency, even in the most severe winter days.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

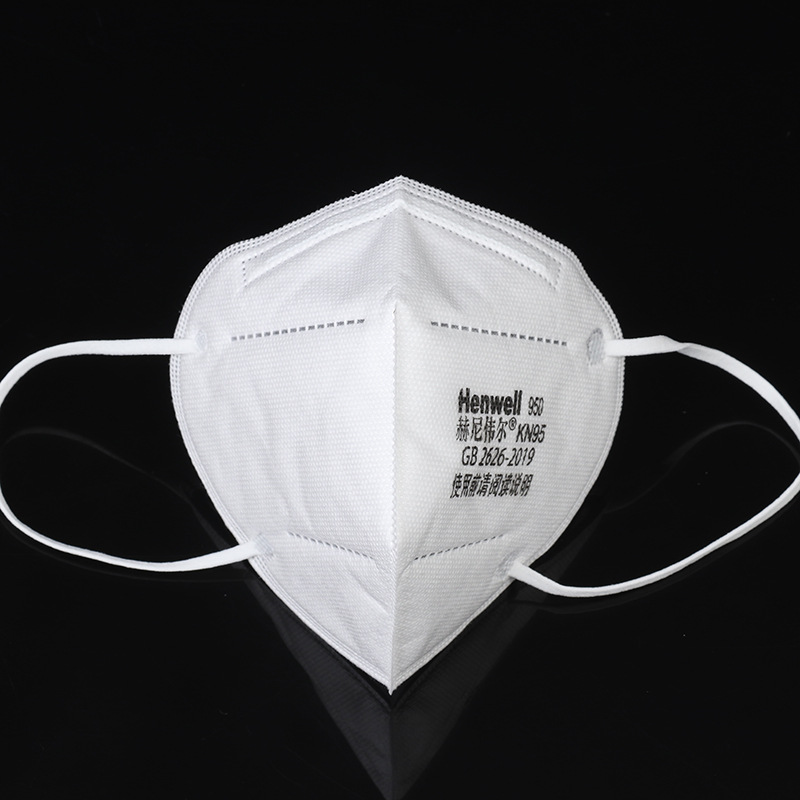

Honeywell Kn95 dust respirator

Honeywell Kn95 dust respirator -

Low -temperature gloves resistant to liquid nitrogen

Low -temperature gloves resistant to liquid nitrogen -

Warm -resistant welding gloves made of oxide leather

Warm -resistant welding gloves made of oxide leather -

Heat -resistant and protecting from burns short welding gloves for labor insurance

Heat -resistant and protecting from burns short welding gloves for labor insurance -

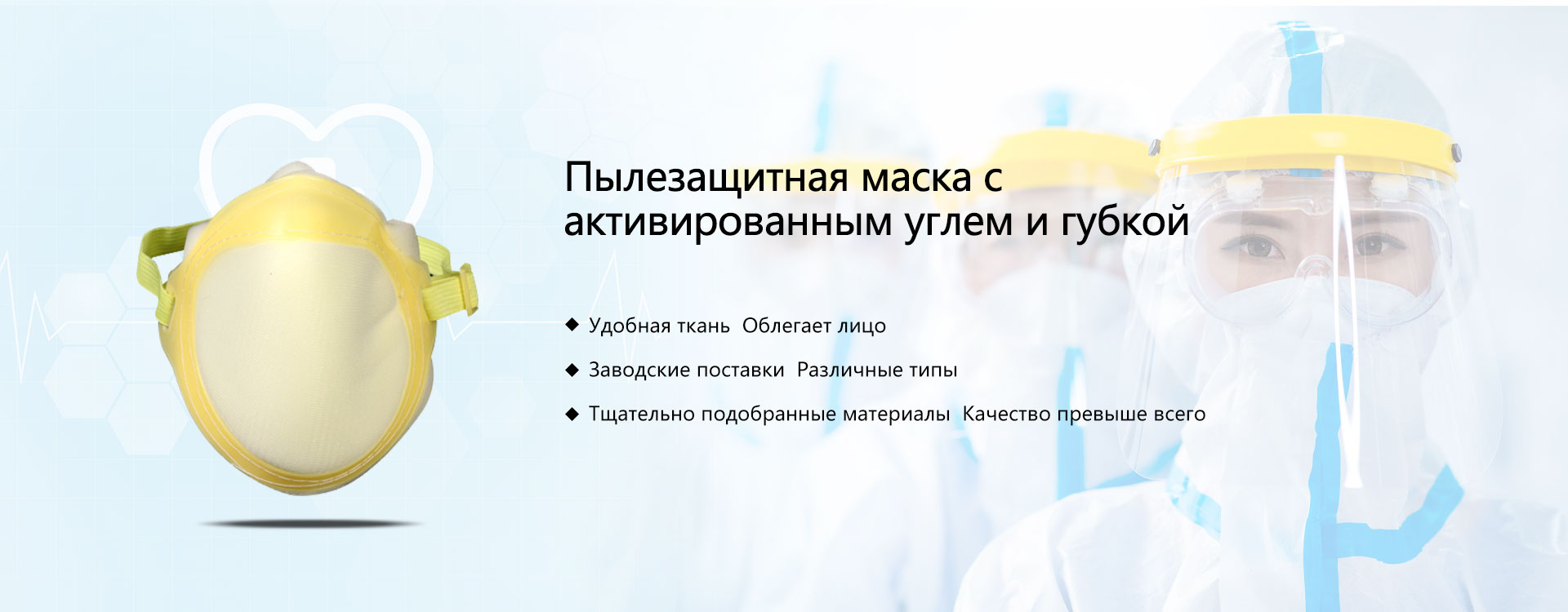

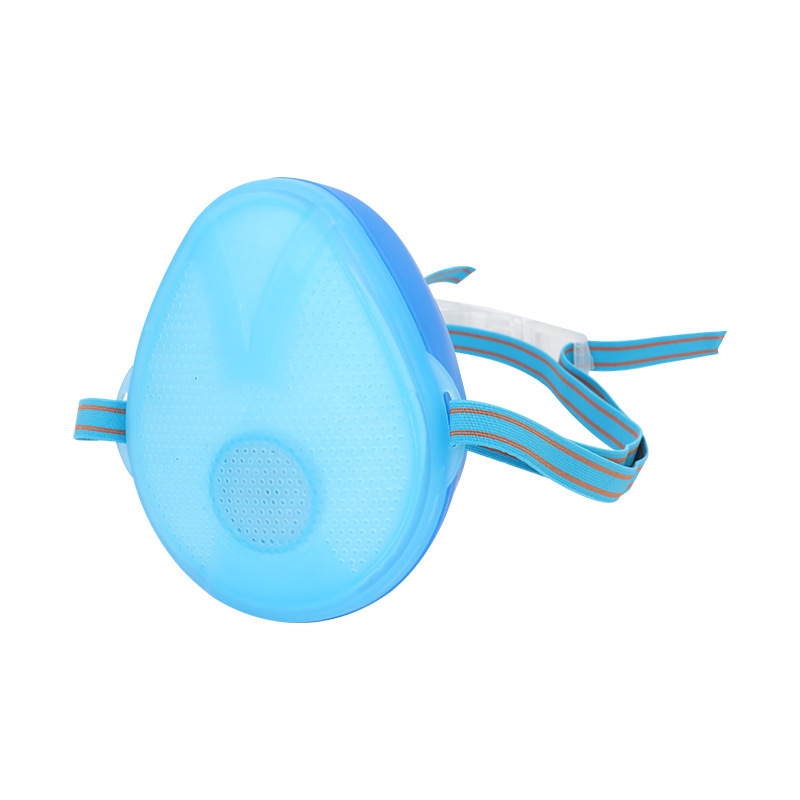

Dust respirator from dust

Dust respirator from dust -

Heat -resistant insulating gloves made of aluminum foil with five fingers

Heat -resistant insulating gloves made of aluminum foil with five fingers -

Thermal insulating anti -burn aramide gloves made of aluminum foil

Thermal insulating anti -burn aramide gloves made of aluminum foil -

Noise reduction and noise insulation Berushi rubber wired bears

Noise reduction and noise insulation Berushi rubber wired bears -

Dust respirator, a summer convenient and breathable mask for protection against solid particles

Dust respirator, a summer convenient and breathable mask for protection against solid particles -

Welding gloves for labor insurance from oxide skin

Welding gloves for labor insurance from oxide skin -

Pyatalpal heat -insulating gloves

Pyatalpal heat -insulating gloves -

Honeywell 950 KN95 masks

Honeywell 950 KN95 masks

Connectedsearch

Related search- Wholesale men's crafts welding gloves of manufacturers

- Manufacturers of ventilation protective glasses from China

- Manufacturers of aluminum foil masks from China

- Cheap types of respirators manufacturers

- Suppliers of wholesale disposable nitrilum gloves

- Wholesale winter leather welding gloves prices

- Cheap masks of aluminum foil basic buyer countries

- Cheap disposable masks from a non -woven material of the factory

- disposable gloves 100 pcs

- Leading Chinese surfaces of leather gloves