welding gloves are thin

## Subtle welding gloves: comfort and protection in one bottle

Welding work is a serious matter, requiring maximum protection. But the protection does not have to be cumbersome and uncomfortable. Thin welding gloves are a successful combination of safety and comfort, which allows you to carry out complex work with marginal accuracy.

### Advantages of thin gloves

The main advantage of thin welding gloves is increased sensitivity. Unlike thick, rough analogues, they allow you to feel the tool and workpiece with greater accuracy, which is especially important when performing small and jewelry welding. This allows you to reduce the amount of marriage and increase labor productivity. In addition, thin gloves are often more flexible and light, which makes the work less tiring, especially with a long process. Of course, the protection level is slightly lower than that of thicker gloves, but for some types of welding this is more than enough.

### Materials and Choice Features

Thin welding gloves are made of different materials, often these are special skin, impregnation, or combined options. When choosing gloves, pay attention to their thickness, material and type of welding for which they are intended. Some gloves have additional amplifiers in the fingers and palms, which increases their wear resistance. It is also important to pay attention to the availability of good ventilation so that the hands do not sweat during work. Correctly selected gloves will provide comfort and reliable protection.

### Precautions

Despite all the advantages of thin welding gloves, remember that they are designed to protect against a certain level of heat and sparks. When working with high temperatures or aggressive environments, it is necessary to use more solid protection. Always check the condition of the gloves before work and replace them at the first signs of wear. Safety is your main priority for any welded work.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

Gloves with five fingers from aluminum foil

Gloves with five fingers from aluminum foil -

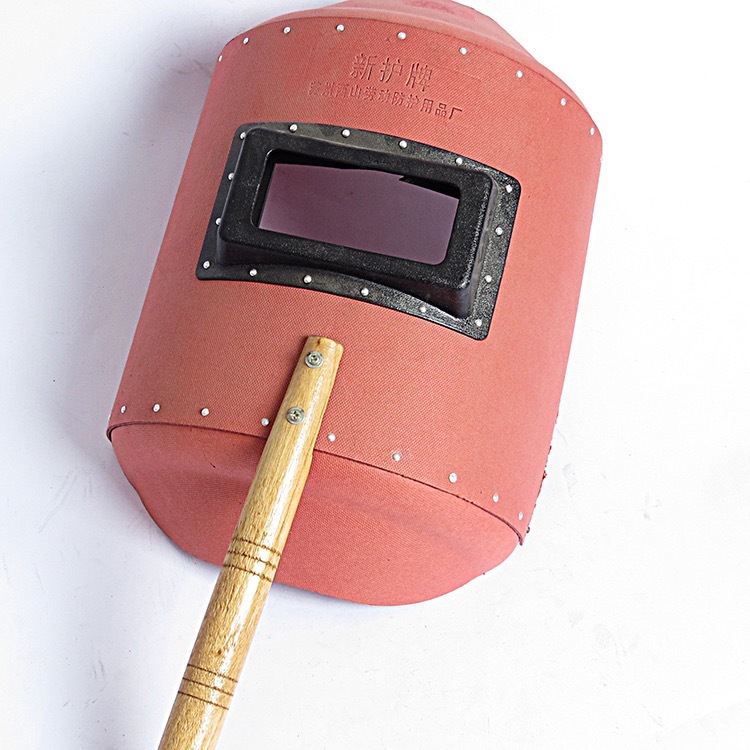

Labor protection mask is a clean shield 7000 mask from dust

Labor protection mask is a clean shield 7000 mask from dust -

Aluminum foil apron

Aluminum foil apron -

Gloves resistant to low temperatures cold storage of antifreeze with liquid nitrogen protection

Gloves resistant to low temperatures cold storage of antifreeze with liquid nitrogen protection -

Protective heat -insulating gloves for construction work

Protective heat -insulating gloves for construction work -

Aluminum foil

Aluminum foil -

Thermal insulating anti -burn aramide gloves made of aluminum foil

Thermal insulating anti -burn aramide gloves made of aluminum foil -

Heat -resistant insulating gloves made of aluminum foil with five fingers

Heat -resistant insulating gloves made of aluminum foil with five fingers -

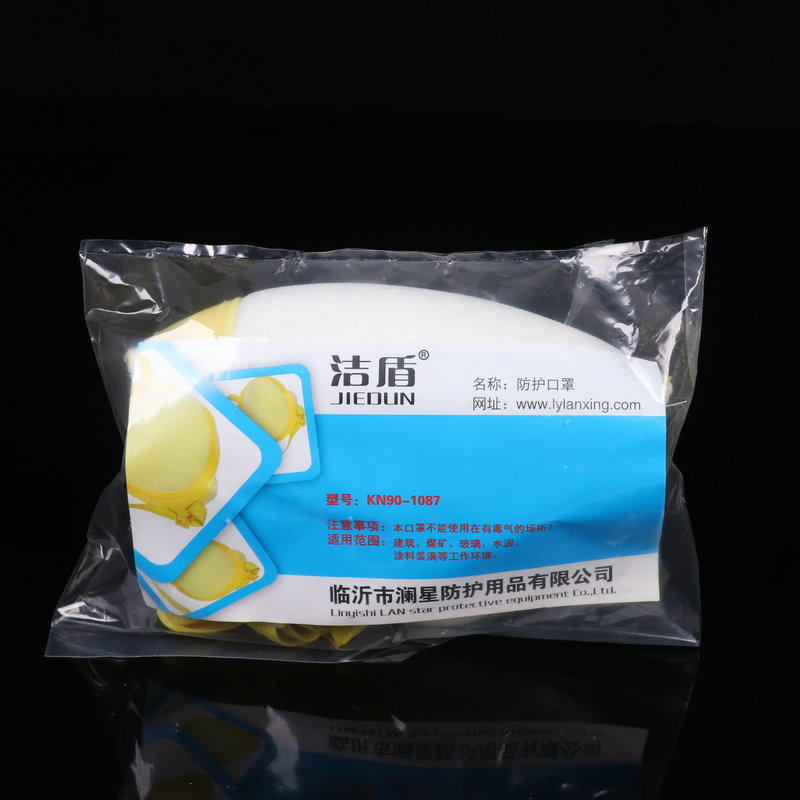

A self -consuming filter mask

A self -consuming filter mask -

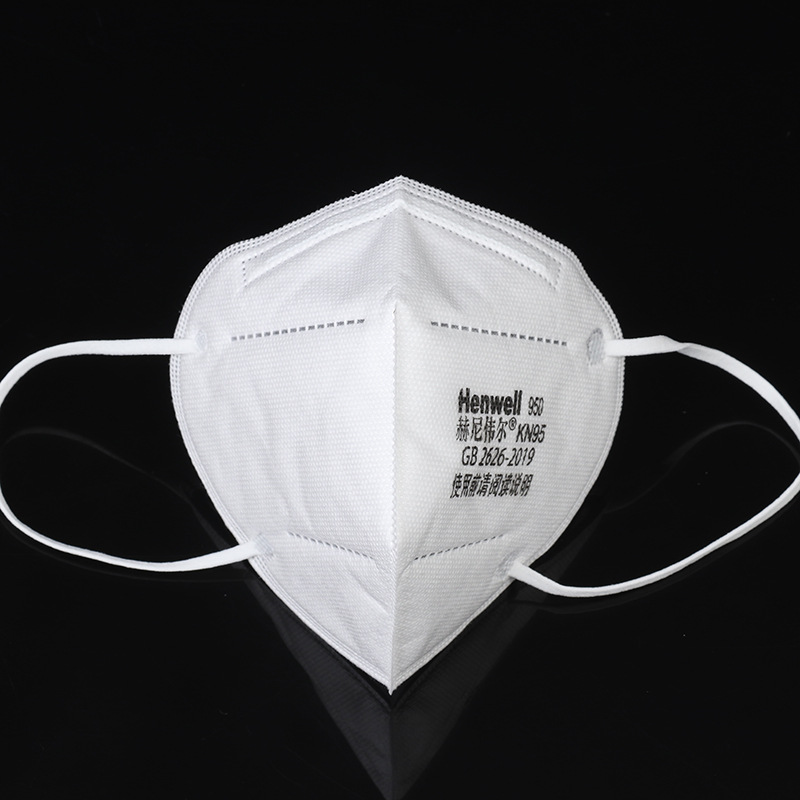

Honeywell 950 KN95 masks

Honeywell 950 KN95 masks -

A dustproof mask with a self -consuming filter

A dustproof mask with a self -consuming filter -

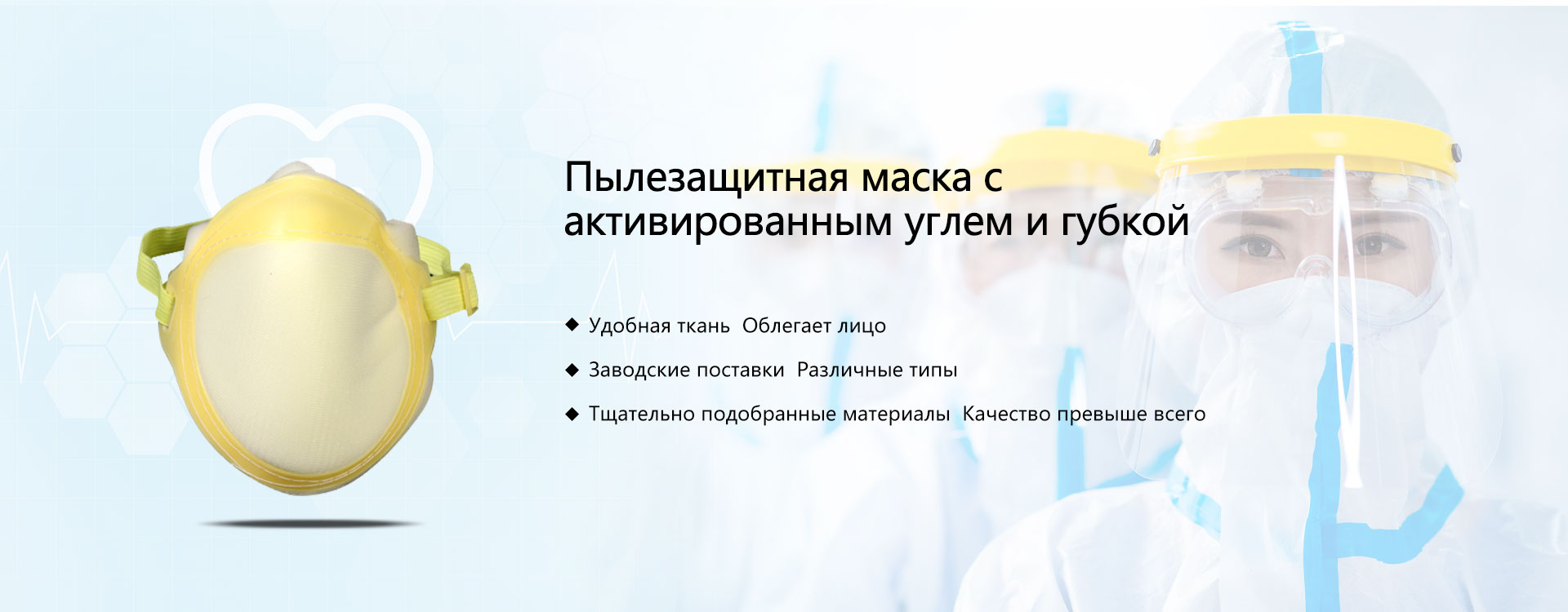

Spongy dustproof respirator with activated coal

Spongy dustproof respirator with activated coal

Connectedsearch

Related search- China disposable packing gloves 100 factories

- Cheap factories masks

- Cheap aluminum foil masks of the main buyer countries

- Cheap disposable masks 3 factories

- Cheap disposable gloves 100pcs factory

- Cheap disposable nitrilum gloves 100pcs price

- Wholesale factories for the production of male gloves

- Chinese suppliers of medical disposable masks

- Chinese protective gloves production plants

- Wholesale warm welds of factories