Disposable masks 3 layers of factory in China

Disposable masks 3 layers of factory in China

China is one of the largest manufacturers of medical products in the world, and disposable masks of a 3-layer structure are no exception. Millions of such masks leave Chinese factories daily, heading for different corners of the planet. But behind mass production is a complex process that requires high quality standards and strict safety measures.

Production technologies: Thrine of three -layer protection

The production of three -layer masks is not just a mechanical connection of three layers of fabric. Each layer performs its own specific function. The outer layer, usually made of polypropylene, serves as protection against external contaminants and moisture. The middle layer is a key element, usually Meltblown (spanbond) is a micro -fiber that has a high filtration ability. He delays the smallest particles, including viruses and bacteria. The inner layer, also from polypropylene, provides comfort when wearing, being soft and pleasant to the skin. All layers are fastened with each other thermal method, ensuring the strength and integrity of the mask. The production process itself is automated using modern machines capable of producing thousands of masks per hour.

Quality and control: the path to reliability

The quality of Chinese masks of a 3-layer structure varies depending on the manufacturer. Therefore, it is extremely important to choose the products of certified factories that have passed the necessary checks and relevant to international standards. The reputation of the plants affects not only the quality of raw materials and the technological process, but also strict control at each stage of production. Regular checks and testing of finished products guarantee the compliance of masks with the declared characteristics. This is the key to the safety and efficiency of user health.

Influence on the world situation: the scale of production and delivery

The scale of the production of disposable masks in China had a significant impact on the global struggle with pandemias. Thanks to the possibilities of fast and mass production, many countries were able to provide the population with the necessary personal protective equipment. However, such high performance also gave rise to problems associated with quality control and the spread of poor -quality products. Therefore, the conscious choice of suppliers and attention to certification remain critical factors.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

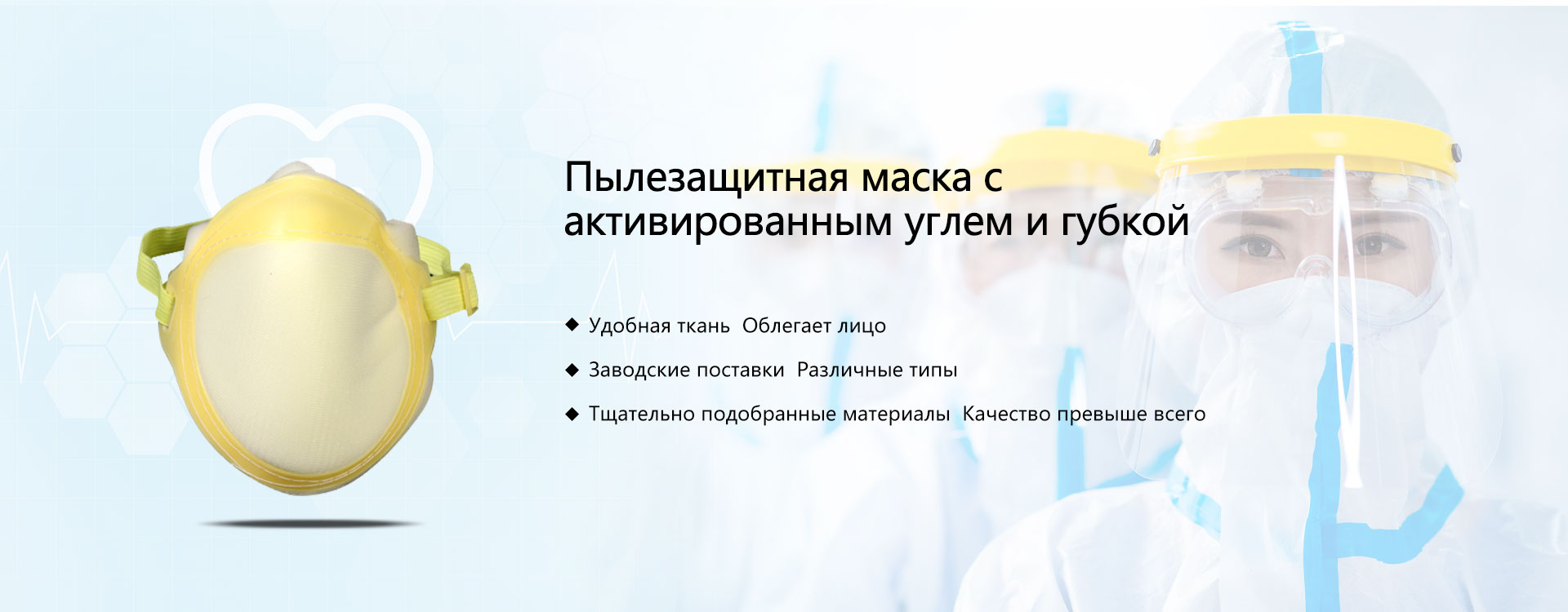

Spongy dustproof respirator with activated coal

Spongy dustproof respirator with activated coal -

Aluminum foil

Aluminum foil -

Welding gloves for labor insurance from oxide skin

Welding gloves for labor insurance from oxide skin -

Heat -resistant and protecting from burns Long welding gloves made of oxide leather

Heat -resistant and protecting from burns Long welding gloves made of oxide leather -

Noise reduction and noise insulation Berushi rubber wired bears

Noise reduction and noise insulation Berushi rubber wired bears -

Disposable mask with three layers of protection

Disposable mask with three layers of protection -

Gloves resistant to high temperatures Aramid insulating gloves

Gloves resistant to high temperatures Aramid insulating gloves -

Clean shield series 950V KN95

Clean shield series 950V KN95 -

Welding gloves made of oxide leather

Welding gloves made of oxide leather -

Clean shield disposable masks ordinary protective masks for adults

Clean shield disposable masks ordinary protective masks for adults -

Thermal insulation cover for legs from aluminum foil protective shoe covers

Thermal insulation cover for legs from aluminum foil protective shoe covers -

Labor protection mask is a clean shield 7000 mask from dust

Labor protection mask is a clean shield 7000 mask from dust

Connectedsearch

Related search- Disposable latex gloves size 100 pieces of factories in China

- Cheap suppliers Open security points

- Cheap sterile disposable gloves basic buyer countries

- Leading Chinese buyers of half -masks for respirators

- gloves disposable packaging 100pcs

- Cheap disposable nitrilum factory gloves

- Leading Chinese search countries welding gloves

- Cheap non-sterile disposable masks 3 main buying countries

- Cheap aluminum foil costume costumes

- Cheap gloves from aluminum foil basic buying countries