Chinese factories for the production of disposable masks from non -woven materials

Chinese factories for the production of disposable masks from non -woven materials

In recent years, especially after the Covid-19 pandemic, the demand for disposable medical masks has increased sharply. China, being the largest manufacturer of textiles and medical equipment, has become a center for the production of these indispensable personal protective equipment. Thousands of factories, large and small, work day and night to satisfy global demand. But behind mass production hides an interesting and complex world.

Technologies and equipment:

The production of disposable masks is a high -tech process that requires specialized equipment. Everything begins with a melt of non -woven material - spanbonda, meltblaun or mixed option. This is a material with the necessary filtration properties. Then, with the help of high -speed machines, the material is cut, formed into the blanks, and then welded by ultrasound or hot air, forming a mask usual to us. Some plants use automated lines where a person’s participation is minimized, while others rely on semi -automated systems that require more labor. Modern equipment allows millions of masks per day.

Working conditions and social responsibility:

The production of masks, like any other industry with mass production, is faced with the issues of ensuring safe and worthy working conditions for workers. Some plants, striving for maximum profit, can ignore the safety and rights of employees who often work in intensive mode and a long working day. However, more and more enterprises are aware of the importance of social responsibility and seek to create the best working conditions, ensuring compliance with security standards and fair wages. The issue of ethical production is becoming increasingly relevant for buyers, and plants focused on long -term development are invested in improving working conditions and advanced training of personnel.

Development prospects:

The market for disposable masks continues to develop dynamically. Manufacturers are constantly looking for ways to improve product quality, increase production efficiency and reduce cost. The introduction of new technologies, for example, the use of more environmentally friendly materials and improve automation, will play a key role in the future of this industry. In addition, an increase in attention to sustainable development and social responsibility will have a significant impact on production methods and the choice of suppliers.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

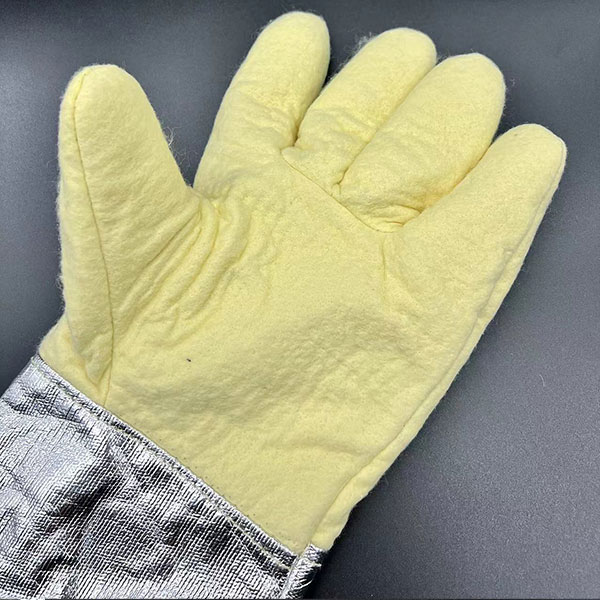

Aramid thermal insulation gloves against aluminum foil burns

Aramid thermal insulation gloves against aluminum foil burns -

Gloves made of heat -resistant aluminum foil with oxide skin to protect labor

Gloves made of heat -resistant aluminum foil with oxide skin to protect labor -

Warm -resistant welding gloves made of oxide leather

Warm -resistant welding gloves made of oxide leather -

Anti -managed gloves

Anti -managed gloves -

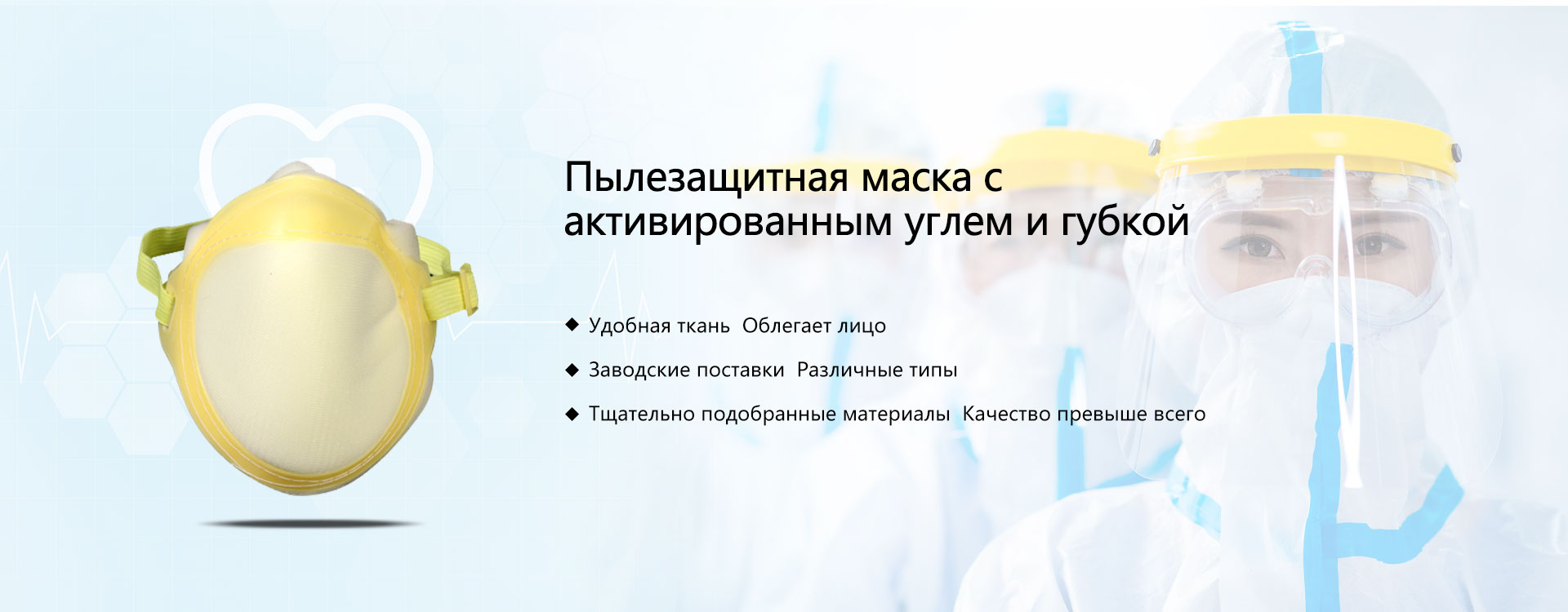

A dustproof mask with a self -consuming filter

A dustproof mask with a self -consuming filter -

Dust respirator from dust

Dust respirator from dust -

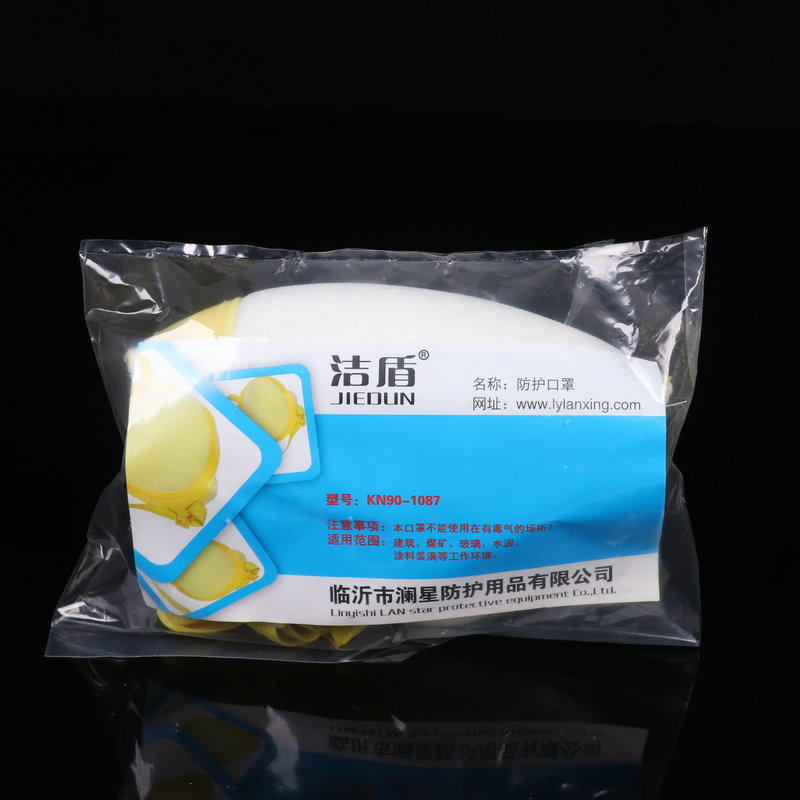

Clean shield protective spongy respirator from dust

Clean shield protective spongy respirator from dust -

Welding gloves for labor insurance from oxide skin

Welding gloves for labor insurance from oxide skin -

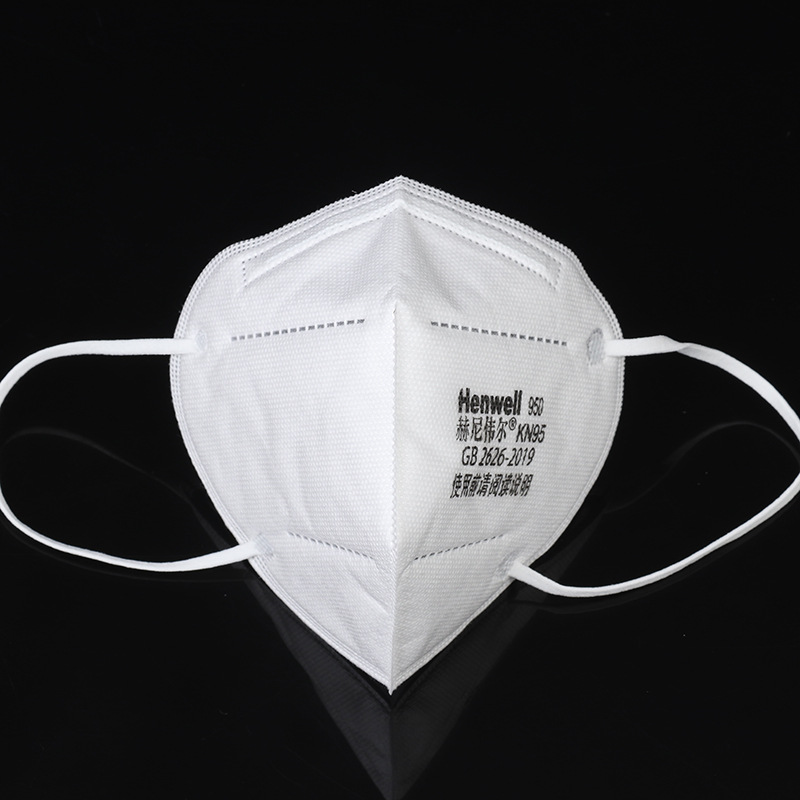

Honeywell Kn95 dust respirator

Honeywell Kn95 dust respirator -

Clean shield disposable masks ordinary protective masks for adults

Clean shield disposable masks ordinary protective masks for adults -

Antistatic workwear

Antistatic workwear -

Anti -School Berushi from a foam with a wire

Anti -School Berushi from a foam with a wire

Connectedsearch

Related search- The main countries of departure for sets from aluminum foil from China

- Cheap winter welding gloves basic buyer countries

- Cheap gas masks GP 7 factories

- Wholesale thin welds of manufacturers

- Cheap disposable observation gloves m basic buyer countries

- Wholesale winter leather welding gloves prices

- Wholesale manufacturers of welding leather gloves

- Cheap aluminum foil sets to protect the legs the main countries-buyer

- Mask is a one -time price

- Prices for disposable gloves in China