Protective gloves of the welder

Protective gloves of the welder: reliable protection for your hands

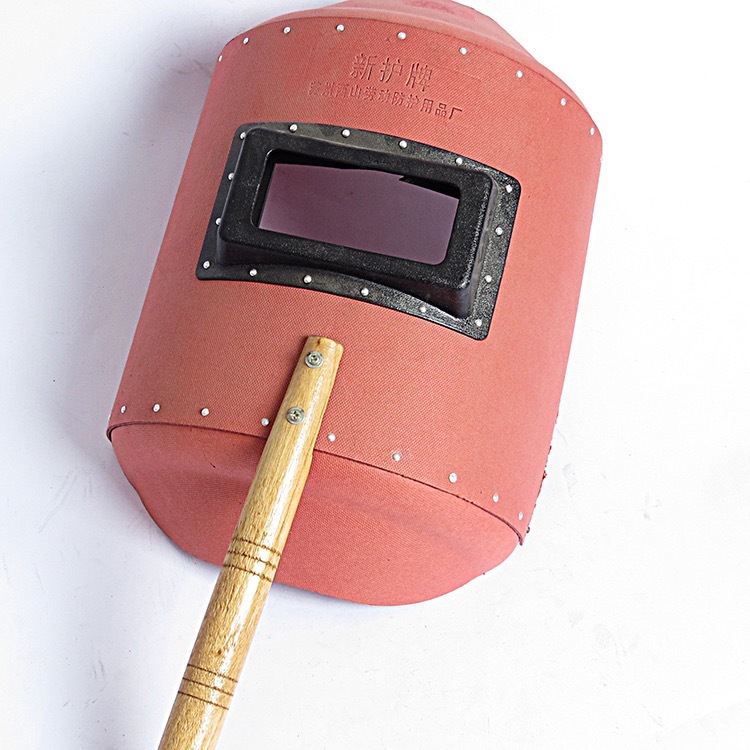

Welding is a dangerous lesson requiring maximum protection. And if the protective mask and overalls are obvious, then the importance of special gloves is often forgotten. But it is precisely the hands of the welder that are subjected to constant exposure to high temperatures, splashes of molten metal, ultraviolet radiation and aggressive chemicals. Therefore, the choice of high -quality protective gloves is not just a precaution, but a necessity that ensures the safety and health of the welder.

Choosing material: Comfort and strength

Welding gloves are made from various materials, each of which has its own advantages and disadvantages. The most common are leather gloves that have high strength and resistance to mechanical damage. The skin protects well from spray of metal and sparks, but requires careful care and can be less flexible than other materials. There are also gloves from a cut, softer and flexible material than whole skin. They provide good protection, but less durable. Modern gloves are often made from combined materials that combine strength and flexibility, which increases the comfort of work. For example, combining the skin with Kevlar increases the resistance to cuts and punctures.

Additional functions: Caring for details

In addition to the main material, additional functions also affect the quality of protective gloves. For example, enhanced seams are the key to durability and prevent ruptures in critical places. Long cuff protects the wrist from burns and spray. The presence of special treatment increases water -repellent properties and protects against chemicals. Properly selected gloves should be tight, but comfortable to sit on the arm without constraining movements. Do not forget about hygienic aspects: should gloves be made of? Breathing? Materials to minimize sweating and discomfort during work.

Proper care: extension of the service life

Even the highest quality gloves require careful handling and regular care. After each work, they need to be cleaned of pollution, dried away from heat sources and stored in a dry place. Timely replacement of worn gloves is an important component of safety. Do not save on protective means: timely replacement of gloves can prevent serious injuries and maintain the health of the welder for many years.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

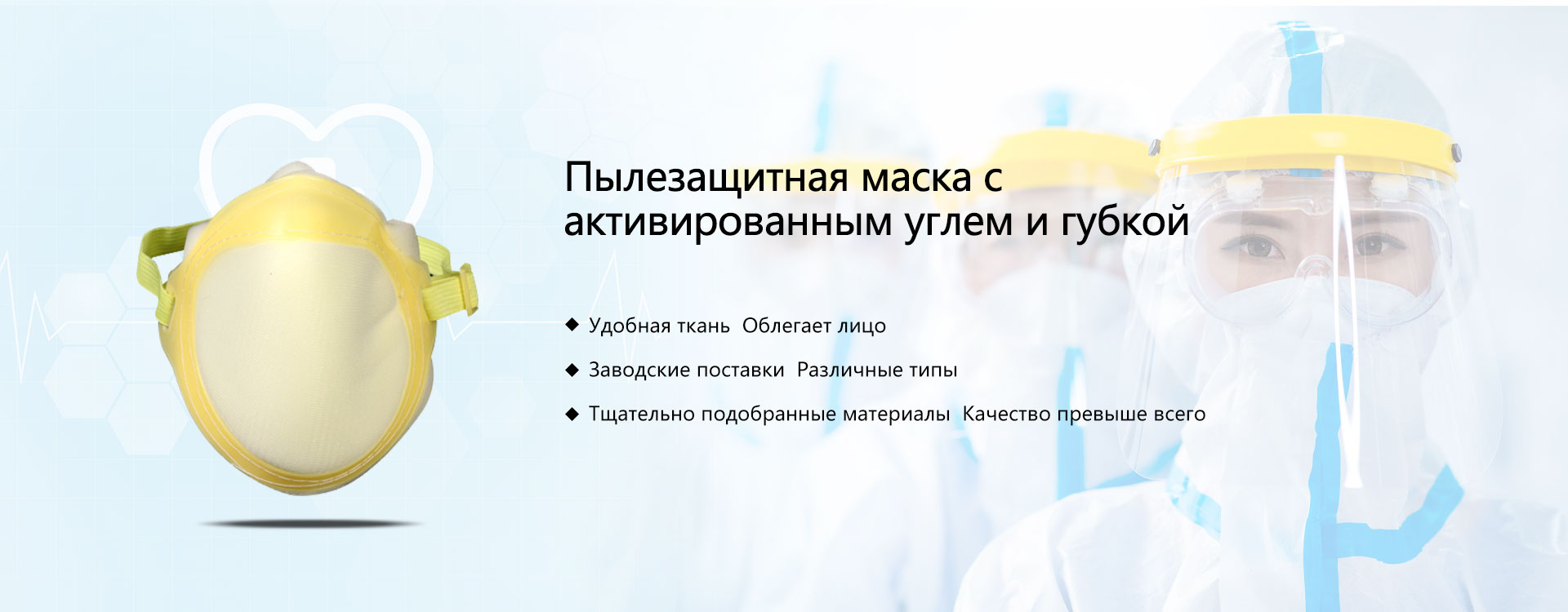

Spongy dustproof respirator with activated coal

Spongy dustproof respirator with activated coal -

Noise reduction and noise insulation Berushi rubber wired bears

Noise reduction and noise insulation Berushi rubber wired bears -

A dustproof mask with a self -consuming filter

A dustproof mask with a self -consuming filter -

Welding gloves made of oxide leather

Welding gloves made of oxide leather -

Gloves made of heat -resistant aluminum foil with oxide skin to protect labor

Gloves made of heat -resistant aluminum foil with oxide skin to protect labor -

Warm -resistant welding gloves made of oxide leather

Warm -resistant welding gloves made of oxide leather -

Dust respirator protection against industrial dust Air permeable KN95

Dust respirator protection against industrial dust Air permeable KN95 -

A self -consuming filter mask

A self -consuming filter mask -

Honeywell Kn95 dust respirator

Honeywell Kn95 dust respirator -

Disposable mask with three layers of protection

Disposable mask with three layers of protection -

Sustainable temperatures insulating gloves from aluminum foil thickened aramid gloves of labor protection gloves

Sustainable temperatures insulating gloves from aluminum foil thickened aramid gloves of labor protection gloves -

Aluminum foil apron

Aluminum foil apron