Production factories for the production of spongy masks in China

Production factories for the production of spongy masks in China

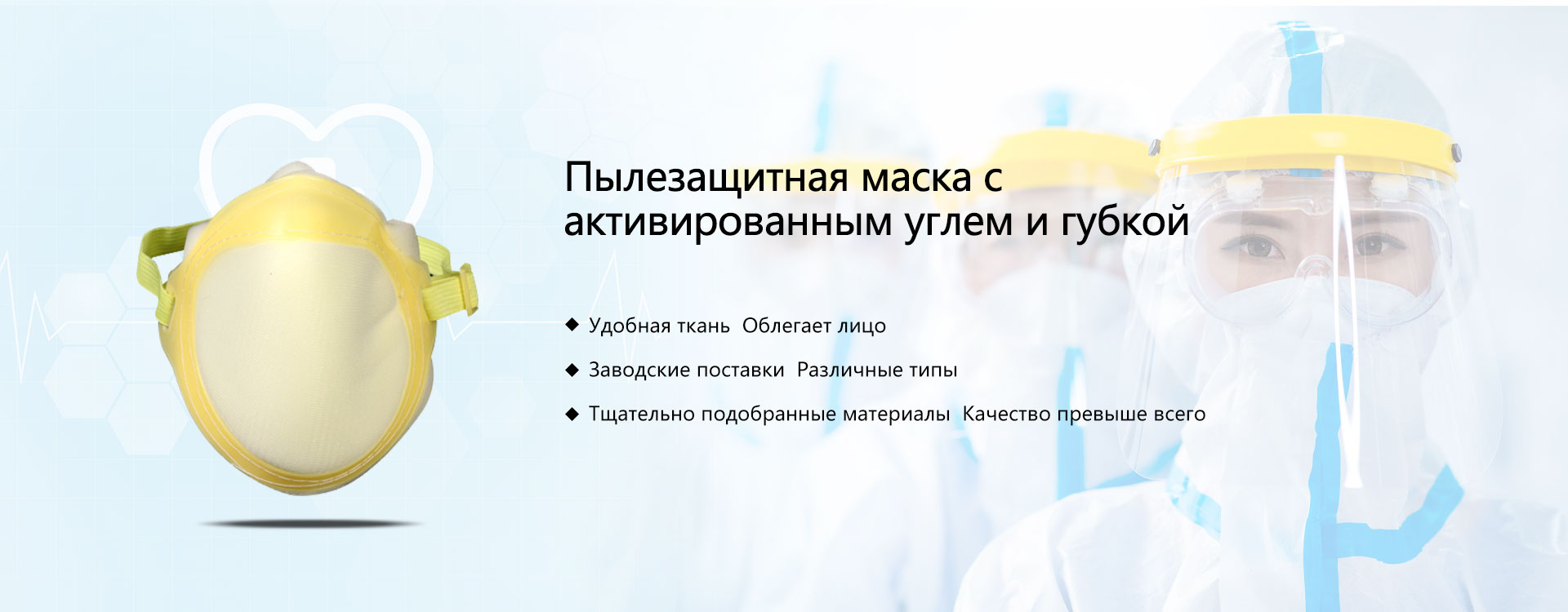

China, being the largest manufacturer of many goods, plays a key role in the production of personal protective equipment, including spongy masks. These masks, although they do not provide the same level of protection as medical ones, are still popular, especially in everyday life, when minimal protection from dust, wind and light drops is needed. The production of these masks is focused on many factories scattered throughout the country, from large industrial centers to smaller production sites.

Production technologies:

The process of manufacturing spongy masks, in general, is quite simple, but requires accurately observing technologies. It begins with the choice of materials: non -woven materials, soft and breathing are most often used. Then, with the help of specialized equipment, the material is cut into blanks of the desired size. The next step is to fasten the layers of the material, if necessary with the addition of filter elements. The final stage is the assembly and packaging of ready -made masks. Modern plants use automated lines that significantly increase performance and provide high quality products. But in small factories manual labor plays an important role, especially at the stages of quality control.

Quality and standards:

Despite the apparent simplicity of the product, the quality of the spongy masks varies depending on the manufacturer. There are strict national standards that many manufacturers must comply with, but the level of control and compliance with these standards may vary. Therefore, it is important to pay attention to the marking and choose products of well -known and proven brands. It is important to understand that spongy masks are not medical products and do not provide complete protection against viruses and bacteria. Their main function is protection against dust and small particles.

Influence on the economy and jobs:

The production of spongy masks creates many jobs in China, from engineers and technicians to workers in workplace and staff on packaging and logistics. This industry is a significant contribution to the country's economy, especially in regions where such production is concentrated. However, it is important to remember the need to ensure fair working conditions and compliance with all the necessary safety standards at these enterprises.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

Welding gloves for labor insurance

Welding gloves for labor insurance -

Disposable mask with three layers of protection

Disposable mask with three layers of protection -

Red -bearing raincoat 8303

Red -bearing raincoat 8303 -

Heat -resistant insulating gloves made of aluminum foil with five fingers

Heat -resistant insulating gloves made of aluminum foil with five fingers -

Aluminum foil apron

Aluminum foil apron -

Pure respirator for protection against solid particles

Pure respirator for protection against solid particles -

Protective mask from aluminum foil

Protective mask from aluminum foil -

Brown welding gloves made of oxide leather

Brown welding gloves made of oxide leather -

Gloves resistant to low temperatures cold storage of antifreeze with liquid nitrogen protection

Gloves resistant to low temperatures cold storage of antifreeze with liquid nitrogen protection -

Thermal insulation cover for legs from aluminum foil protective shoe covers

Thermal insulation cover for legs from aluminum foil protective shoe covers -

Noise reduction and noise insulation Berushi rubber wired bears

Noise reduction and noise insulation Berushi rubber wired bears -

Aluminum foil

Aluminum foil

Connectedsearch

Related search- Prices for 50 disposable masks from China

- Protective equipment

- The best countries-buying countries for wholesale gloves

- Factory cheap filter respirators

- Cheap spongy masks of factories

- Manufacturers of red welding gloves in China

- Respiratorial respiratory protection products

- Disposable gloves are medical

- Cheap protective glass suppliers

- Cheap respirators of individual price protection prices