Cheap types of factories protective glasses

Cheap types of factories protective glasses

Protective glasses are an integral part of safety at any production. But far from always expensive models justify their price. Many factories use more budget options, while ensuring a sufficient level of protection for their employees. Of course, it is important to understand what? Cheap? It does not always mean? Bad?, but requires an attentive approach to choosing. The key factor is the compliance of points with specific working conditions.

1. Glasses with polycarbonate lenses.

Polycarbonate is one of the most common materials for lenses of protective glasses. It has high impact resistance, withstanding even strong blows with small particles. At the same time, polycarbonate is relatively light and transparent, which makes it convenient for prolonged work. Glasses with polycarbonate lenses are the most common and affordable option in many factories. They effectively protect their eyes from dust, spray of liquids and small fragments, which makes them a suitable option for many production processes. Of course, the degree of protection depends on the specific model of glasses and the presence of additional elements, for example, lateral protection.

2. Glasses with protection against ultraviolet radiation.

In some factories, especially those where welding equipment is used or work is carried out in the open air, protection against ultraviolet radiation is necessary. There are relatively inexpensive models of protective glasses equipped with a special coating that blocks harmful UV rays. They not only protect the eyes from damage, but also prevent the development of various eyes of the eyes associated with prolonged exposure to ultraviolet radiation. The choice of such points is especially important for maintaining employees' health.

3. Simple protective glasses with lateral protection.

For some types of work, there are sufficiently simple protective glasses with lateral protection made of plastic or rubber. They prevent dust and particles from the side sides, which is especially true when working with grinding machines or other tools that create a large amount of dust and fragments. These glasses are usually the cheapest, but they should be used only where there is no risk of getting large or high -speed objects.

In conclusion, it is worth emphasizing that the choice of the type of protective glasses depends on the specifics of the work. Do not save on safety, choosing too cheap models if they do not meet the requirements of specific working conditions. It is important to remember that the health of the eyes is priceless.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

Gloves resistant to high temperatures Aramid insulating gloves

Gloves resistant to high temperatures Aramid insulating gloves -

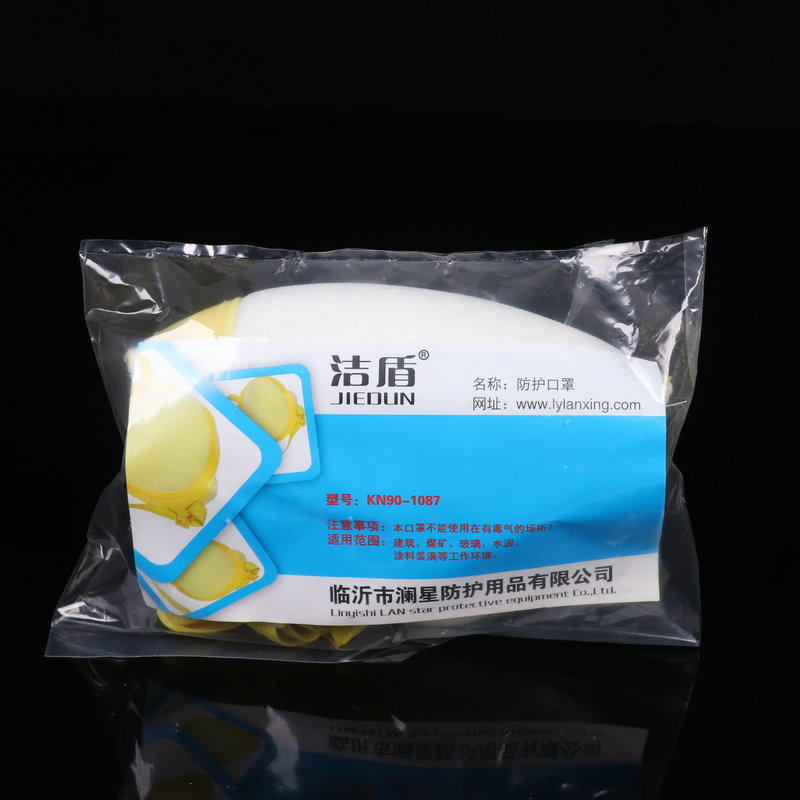

Dust respirator from dust

Dust respirator from dust -

Pure respirator for protection against solid particles

Pure respirator for protection against solid particles -

A self -consuming filter mask

A self -consuming filter mask -

Sustainable temperatures insulating gloves from aluminum foil thickened aramid gloves of labor protection gloves

Sustainable temperatures insulating gloves from aluminum foil thickened aramid gloves of labor protection gloves -

Brown welding gloves made of oxide leather

Brown welding gloves made of oxide leather -

Gloves made of heat -resistant aluminum foil with oxide skin to protect labor

Gloves made of heat -resistant aluminum foil with oxide skin to protect labor -

Thermal insulating anti -burn aramide gloves made of aluminum foil

Thermal insulating anti -burn aramide gloves made of aluminum foil -

Heat -resistant and protecting from burns Long welding gloves made of oxide leather

Heat -resistant and protecting from burns Long welding gloves made of oxide leather -

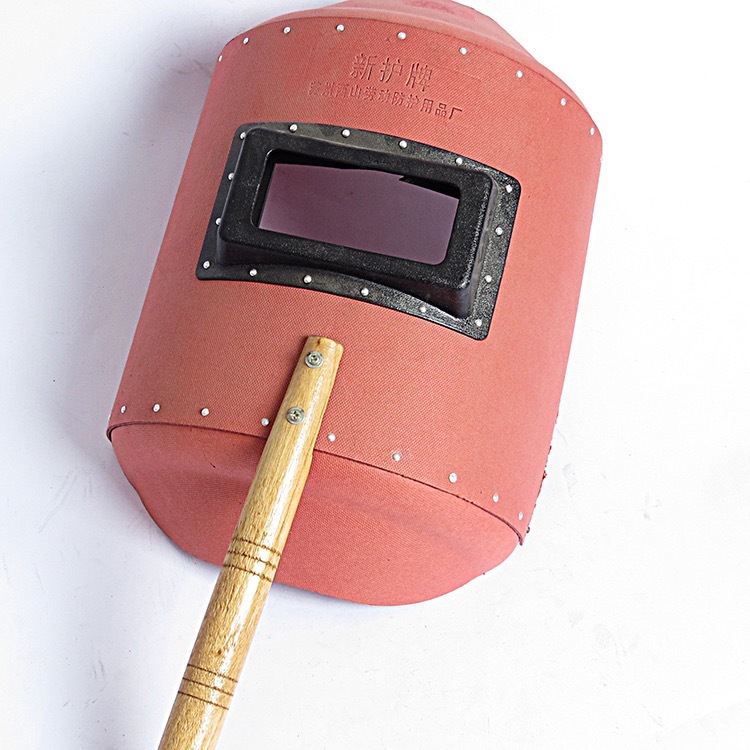

Semi -automatic manual welding helmet

Semi -automatic manual welding helmet -

Low -temperature gloves resistant to liquid nitrogen

Low -temperature gloves resistant to liquid nitrogen -

Protective mask from aluminum foil

Protective mask from aluminum foil

Connectedsearch

Related search- Cheap disposable gloves 100 pairs manufacturers

- Prices for leather gloves in China

- Cheap welders gloves 5 factories

- Cheap disposable masks from non -woven material suppliers

- Clothing factories with protection from cuts in China

- Leading buyers of filter gas masks in China

- Cheap gloves of welders 5 manufacturers

- Cheap gas masks of 5 main countries-buyers

- Cheap working welding gloves manufacturers

- Cheap respirators factories