The choice of welding gloves

The choice of welding gloves

Welding is a work that requires not only skill, but also reliable protection. And one of the most important elements of this protection is welding gloves. The wrong choice can lead to serious burns, cuts and other injuries. Therefore, the choice of gloves must be approached with all seriousness. Do not save safety!

Choosing material: leather or Kevlar?

There are many welding gloves from various materials on the market. The most common are leather and Kevlar. Leather gloves are a classic of the genre, tested by time. They protect well from sparks and splashes of molten metal, quite strong and durable. However, the skin can wear out quickly with intensive work and requires regular care. Kevlar gloves, in turn, are lighter and flexible, provide excellent protection against heat and puncture. The choice between skin and Kevlar depends on specific working conditions and personal preferences. For example, for working with thin metal, more flexible Kevlar gloves are better suited.

Length and size - the key to comfort and safety

The length of the gloves is another important parameter. Longer gloves provide more reliable hands and forearm. However, too long gloves can limit freedom of movement. Therefore, you need to find the middle ground, given the specifics of the work performed. The size is no less important. Gloves should sit tightly on the arm without constraining movements, but not to hang out either. Too cramped gloves will cause discomfort, and too free - will not provide the necessary protection. Before buying, be sure to try on gloves.

Care and storage - we extend the service life

Even the highest quality welding gloves wear out over time. To extend their service life, it is necessary to care for them correctly. After the glove, the gloves should be cleaned of the remains of metal and slag, dried in a well -ventilated place and stored in a dry place, in was given from heat and moisture sources. Regular care for gloves will allow you to use them longer, providing yourself with reliable protection during welding.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

Welding gloves for labor insurance

Welding gloves for labor insurance -

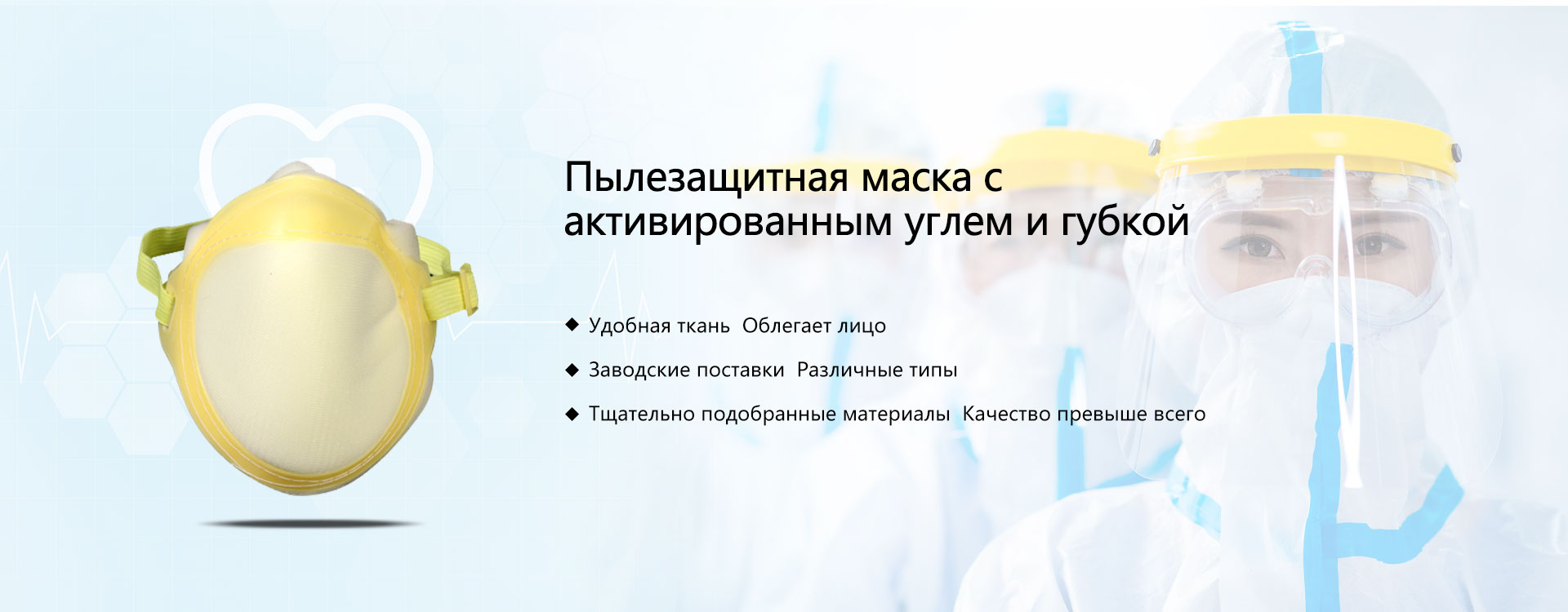

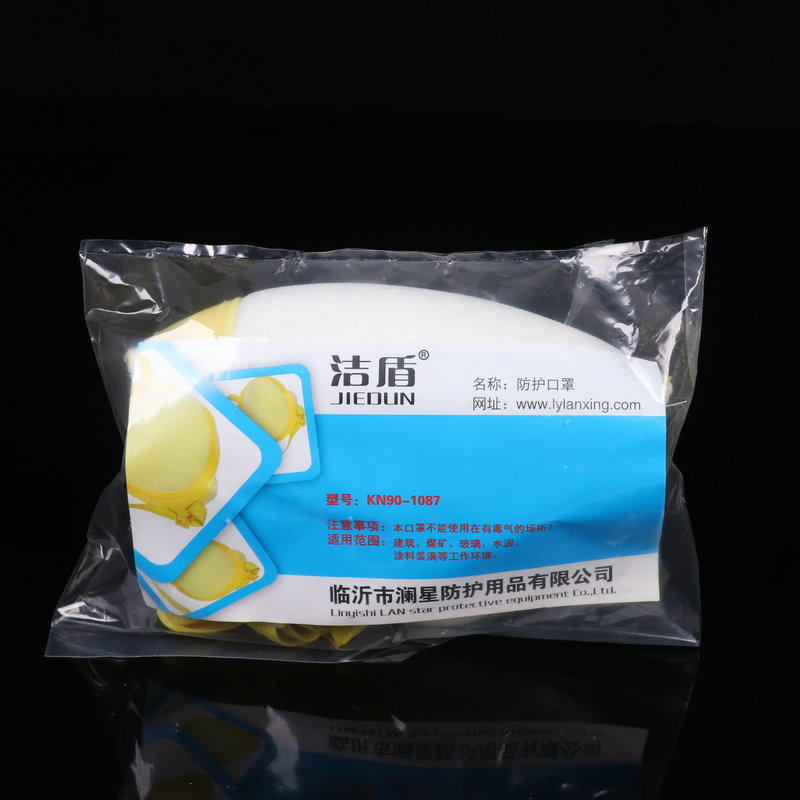

Clean shield protective spongy respirator from dust

Clean shield protective spongy respirator from dust -

Spongy dustproof respirator with activated coal

Spongy dustproof respirator with activated coal -

Protective heat -insulating gloves for construction work

Protective heat -insulating gloves for construction work -

Disposable mask with three layers of protection

Disposable mask with three layers of protection -

Dust respirator protection against industrial dust Air permeable KN95

Dust respirator protection against industrial dust Air permeable KN95 -

Gloves made of heat -resistant aluminum foil with oxide skin to protect labor

Gloves made of heat -resistant aluminum foil with oxide skin to protect labor -

Warm -resistant welding gloves made of oxide leather

Warm -resistant welding gloves made of oxide leather -

Gloves with a thickening to protect against high temperatures and thermal insulation

Gloves with a thickening to protect against high temperatures and thermal insulation -

Welding gloves made of oxide leather

Welding gloves made of oxide leather -

Dust respirator from dust

Dust respirator from dust -

Thermal insulating anti -burn aramide gloves made of aluminum foil

Thermal insulating anti -burn aramide gloves made of aluminum foil

Connectedsearch

Related search- Welding gloves in China

- Cheap filtered breathing apparatus manufacturers

- Chinese manufacturers of respirator types

- Suppliers of cheap masks

- Cheap protective funds from cuts manufacturers

- Disposable masks factories in China

- The main countries-buyers of wholesale welds

- Cheap manufacturers of sterile disposable gloves

- Cheap open protective glasses basic buyer countries

- Wholesale manufacturers of working welding gloves